The Center for Research in Emergent Manufacturing (CREM), which started as the ambitious idea of two UMBC researchers in 2019, is launching a major new project with the U.S. Army and other partners this year. UMBC has received an initial amount of more than $3 million to fund the first year of the project, which will investigate ways to digitize the army’s supply chain.

CREM is led by director Nilanjan Banerjee, professor of computer science and electrical engineering, and associate director Donna Ruginski, associate vice president for center development in the Office of Research and Creative Achievement at UMBC. It aims to help manufacturers reap the benefits, and manage the risks, of new manufacturing approaches increasingly centered around computer systems—a concept known as digital manufacturing.

Since its founding, the center has already established programs to educate manufacturing professionals in cybersecurity. The new project will significantly advance the center’s research activities and impact.

“The partnership with the army is an important step in our evolution as a research center. We will be working on cutting edge problems for the Army in the areas of digitization,” says Banerjee.

“We’re new and full of energy,” says Ruginski. “I’m confident we’ll make a difference.”

From spinning jennies to generative AI

Manufacturing has come a long way since the 18th-century textile industry was revolutionized by the invention of machines such as spinning jennies, which greatly increased the amount of thread a single worker could produce. Since then, new technologies, such as the electric grid in the early 20th century and computers in the mid-century, brought further waves of change to the way goods are made.

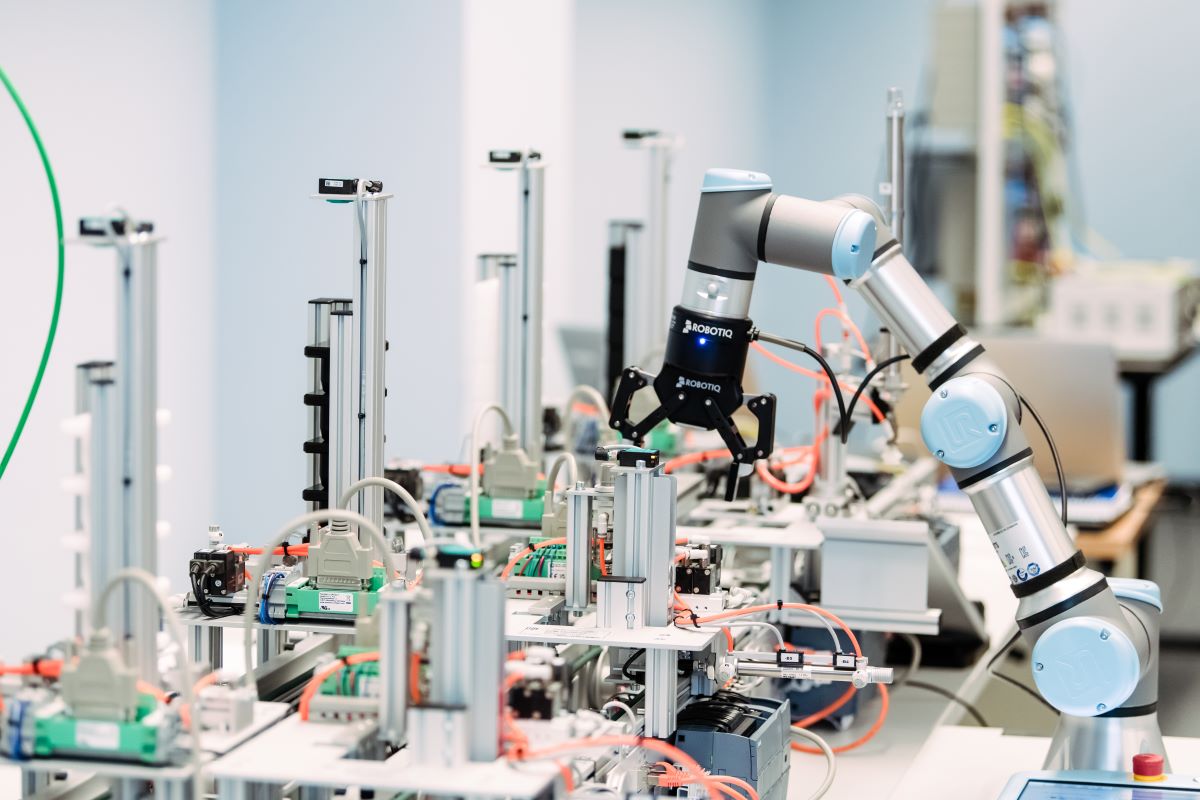

On a modern factory floor, robots and their computer control systems increasingly take the place of humans in the assembly process, and the future of manufacturing will likely be even more automated and digitized than it is today. Companies are increasingly turning to new technologies such as smart sensors, AI, cloud computing, and advanced analytics to increase the flexibility, resilience, and efficiency of their operations. This transformation—called industry 4.0—holds enormous promise to improve living standards by increasing productivity, but it also comes with some perils, including vulnerability to cyberattacks.

Training and research

UMBC aims to help manufacturers navigate the industry 4.0 shift. Part of that mission will be to educate future workers in digital manufacturing, be they UMBC students or working professionals looking to expand their skill set.

In 2020, under the auspices of CREM, Banerjee and Ruginski launched the Cybersecurity for Manufacturing Operational Technology (CyMOT) program to train manufacturing professionals in best practices for preventing cyberattacks on manufacturing operations. Through the program, CREM has educated more than 300 manufacturers from small and medium-sized businesses.

“The manufacturing sector has suffered a number of cyberattacks recently, so it’s important to make sure people in the sector are trained in cybersecurity,” says Banerjee.

CREM also hosts a state-of-the-art cybersecurity training and research facility, called a cyber range, specifically focused on digital manufacturing technology—one of only a few in the country. In the coming months, the cyber range will move to a new and dedicated location on the UMBC campus.

“The research and training efforts conducted by CREM under Dr. Banerjee’s leadership have wide-ranging consequences,” says Karl Steiner, the vice president for research and creative achievement at UMBC. “As digital manufacturing rapidly becomes a national and global standard, it is critical to develop adaptive cybersecurity strategies and protocols to secure the global supply pipeline. I am delighted that CREM is supported through one of three major research partnerships that UMBC developed in recent years with the U.S. Army.”